The effect it will have on auto workshops in Australia...

As we know, auto workshops and work sites with loads of vehicles coming and going, or diesel motors running, can be noisy, dirty places. So it's not surprising that workers, employers, and visitors are concerned about the air quality in these workplaces, and what it can be doing to people's health.

SafeWork Australia has Workplace Exposure Standards (WES) in place for airborne contaminants, which are the maximum level of an airborne contaminant that most people can be exposed to without harm to their health. The WES cover everything from asbestos to silica, to the chemicals and vapours often found around vehicles. The current WES are guidelines for best practice standards.

However, the WES are being transitioned to Workplace Exposure Limits (WEL), which will be an exposure level that must not be exceeded. WEL will come into effect on 1 December 2026.

Once the new WEL comes into effect, these airborne contaminants typically found in diesel and petrol emissions should be monitored:

Airborne Contaminant | About the Contaminant | Current Workplace Exposure Standards (WES)* - up to 1st Dec 2026 | Proposed Workplace Exposure Limits (WEL)* - after 1st Dec 2026 |

|---|---|---|---|

Diesel Particulate Matter (DPM) | The soot generated by diesel engines. Classified as a Group 1 carcinogen - associated with lung and bladder cancer and other respiratory diseases | No current WES | 0.01mg/m3 |

Carbon Monoxide (CO) | Found in petrol vehicle exhaust gas. Causes headache, dizziness, loss of consciousness | 34mg/m3 | 23mg/m3 |

Nitrogen Dioxide (NO2) | Found in diesel vehicle exhaust gas and petrol. Causes respiratory irritation, bronchitis, long-term lung damage | 5.6mg/m3 | 5.6mg/m3 |

*measured as 8 hour time weighted average

What can be done to improve air quality around vehicle maintenance activities

Workshop practices - limiting engine running and unnecessary idling, ensuring appropriate PPE is worn, maintaining cleanliness

Health and Safety practices - better education and Standard Operating Procedures, monitoring of air quality

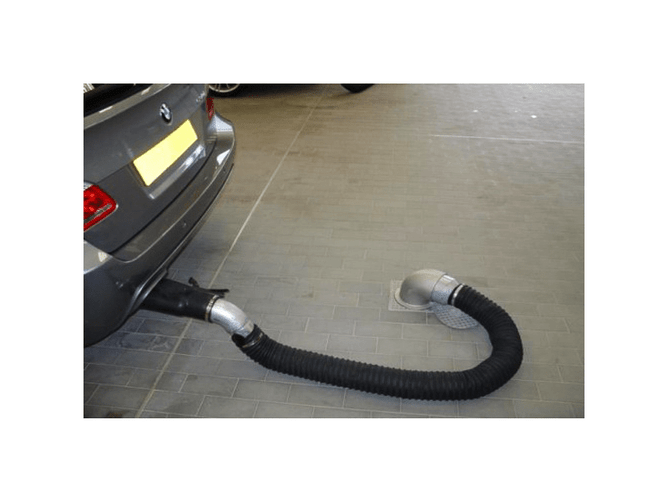

Improving ventilation – adequate natural ventilation, workshop extraction systems, emissions capture/LEV systems, improved HVAC

Dynamic Engineering Australia are ventilation experts who can engineer solutions using quality products to best suit your application.

We stock a range of off-the-shelf vehicle exhaust fume extraction products, which are of high quality (made in Italy), and with long-lasting performance.

See our range of AerService Equipments vehicle exhaust fume extraction here.